450 Avenue Abbé Kahozi Quartier Makutano Commune de Lubumbashi Ville

Electric motors and generators

-

Asynchronous motors

-

Synchronous motors

-

DC motors

Asynchronous motors

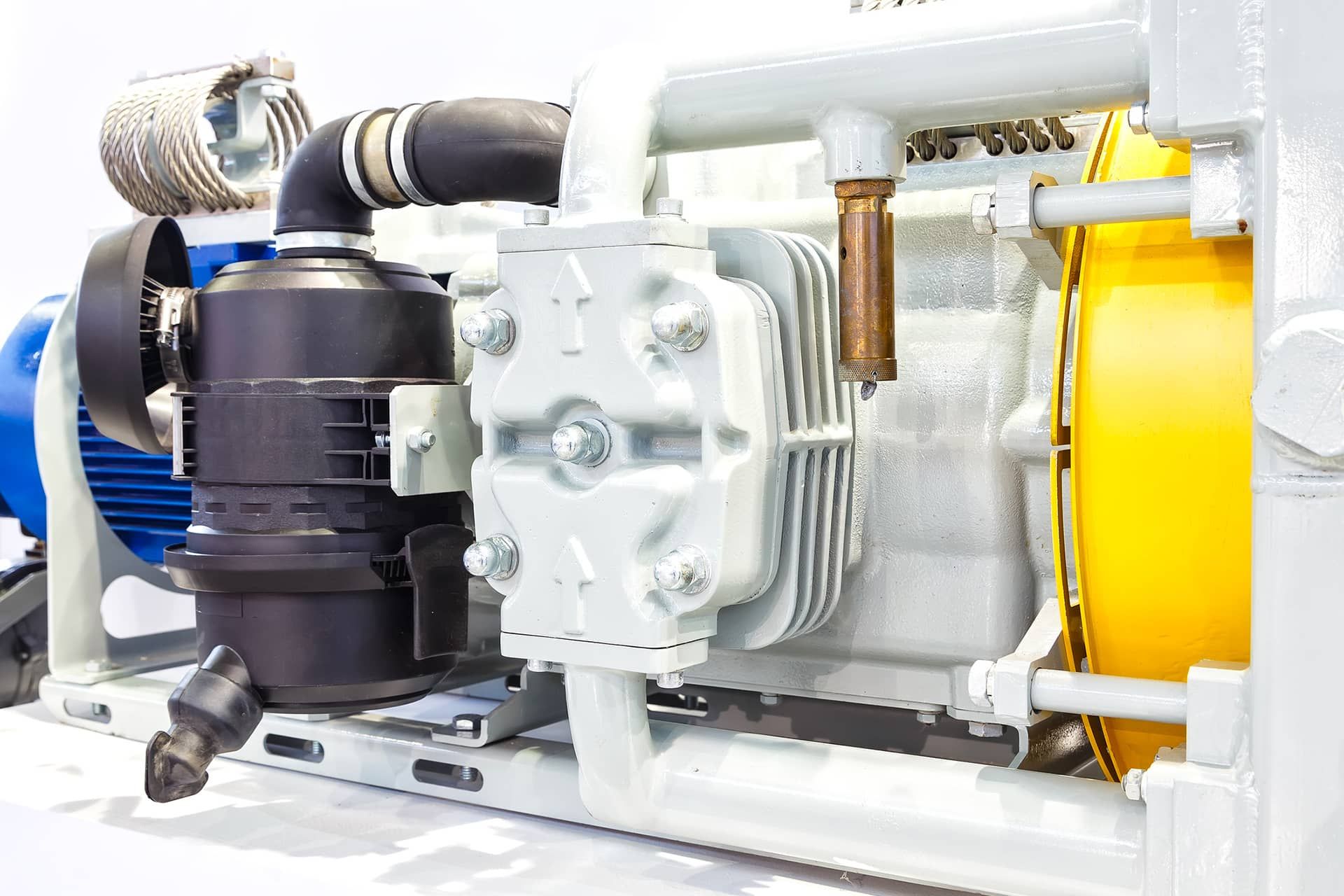

Asynchronous motors with a squirrel-cage rotor make up a significant part of the family of AC electric motors - converters of electromagnetic energy from a single or three-phase network into mechanical energy of rotation of the motor shaft.

An asynchronous electric motor with a squirrel-cage rotor contains two main parts: stationary and rotating. The stationary part - the stator - consists of a core of one configuration or another, one or several windings laid in the grooves of the core and structural parts: a frame, fasteners, etc. The moving part - the rotor - consists of a core, a squirrel-cage winding laid in its slots, and structural parts, with the help of which it is possible to rotate the moving part relative to the stationary one: a shaft, support bearings, fasteners, etc. The design of such motors is the simplest of all types of electrical machines.

Application of asynchronous motors

Extreme simplicity of design and low cost of production, as well as the emergence of flexible in programming frequency converters determined the almost widespread use of asynchronous motors with a squirrel cage rotor in industrial electric drives. Single-phase and three-phase asynchronous motors are used:

-

In metallurgical production: in automated drives of equipment for rolling and drawing mills, foundry.

-

In metalworking production: in automated drives of machine tools and machining centers, lifting and crane equipment, conveyors, etc.

-

In mechanical assembly production: in drives of manipulators, conveyors, compressor equipment.

-

In the mining industry: in drilling and excavator equipment, conveyors, etc.

-

In pumping, ventilation, compressor equipment.

-

In construction: in crane equipment, equipment for the preparation and transportation of building materials.

-

In the household sphere: in hand-held power tools, laundry, kitchen and office equipment.

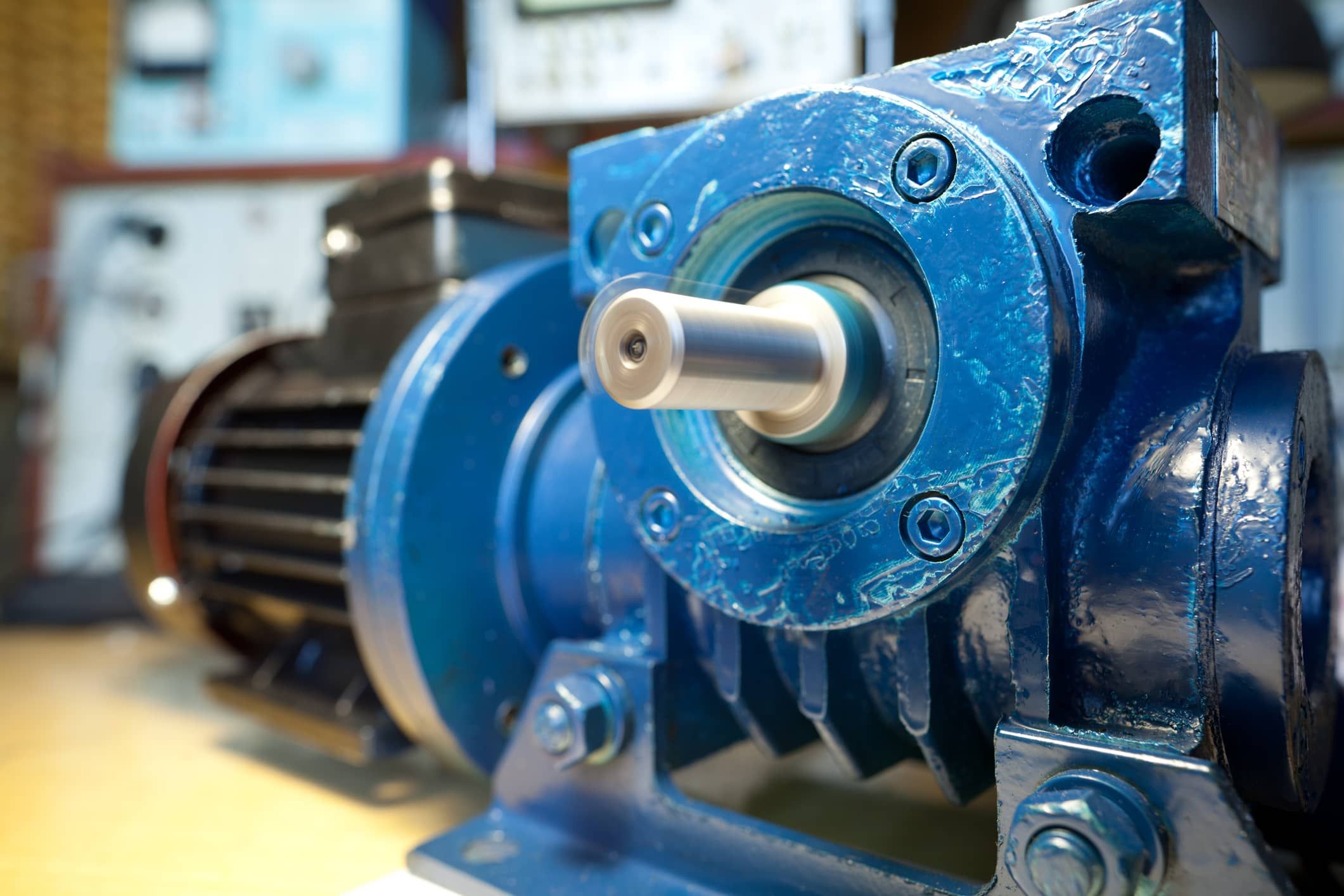

Synchronous motors

Our industries

A synchronous electric motor is a device that operates on an alternating current network. In a synchronous machine, the rotor speed corresponds to the speed of the magnetic field. When choosing an electric motor, it is necessary to consult with the manufacturer.

Synchronous electric motors are used where starting and stopping occur quite rarely (conveyors, etc.), that is, the motors operate around the clock for a fairly long time. Operation in such conditions is explained by the fact that synchronous motors operate with cos φ close to 1, and can supply reactive power to the network, as a result of which the power factor of the network improves and its consumption decreases, which is important for enterprises.

Synchronous electric motors are widely used in the metallurgical and metalworking industries, at oil production facilities, at pumping stations of city water canals, in the pulp and paper industry and other industries.

Application of synchronous motors for the drive:

-

Powerful fans

-

Mills

-

Conveyors

-

Exhausters

-

Compressors

-

Crushers

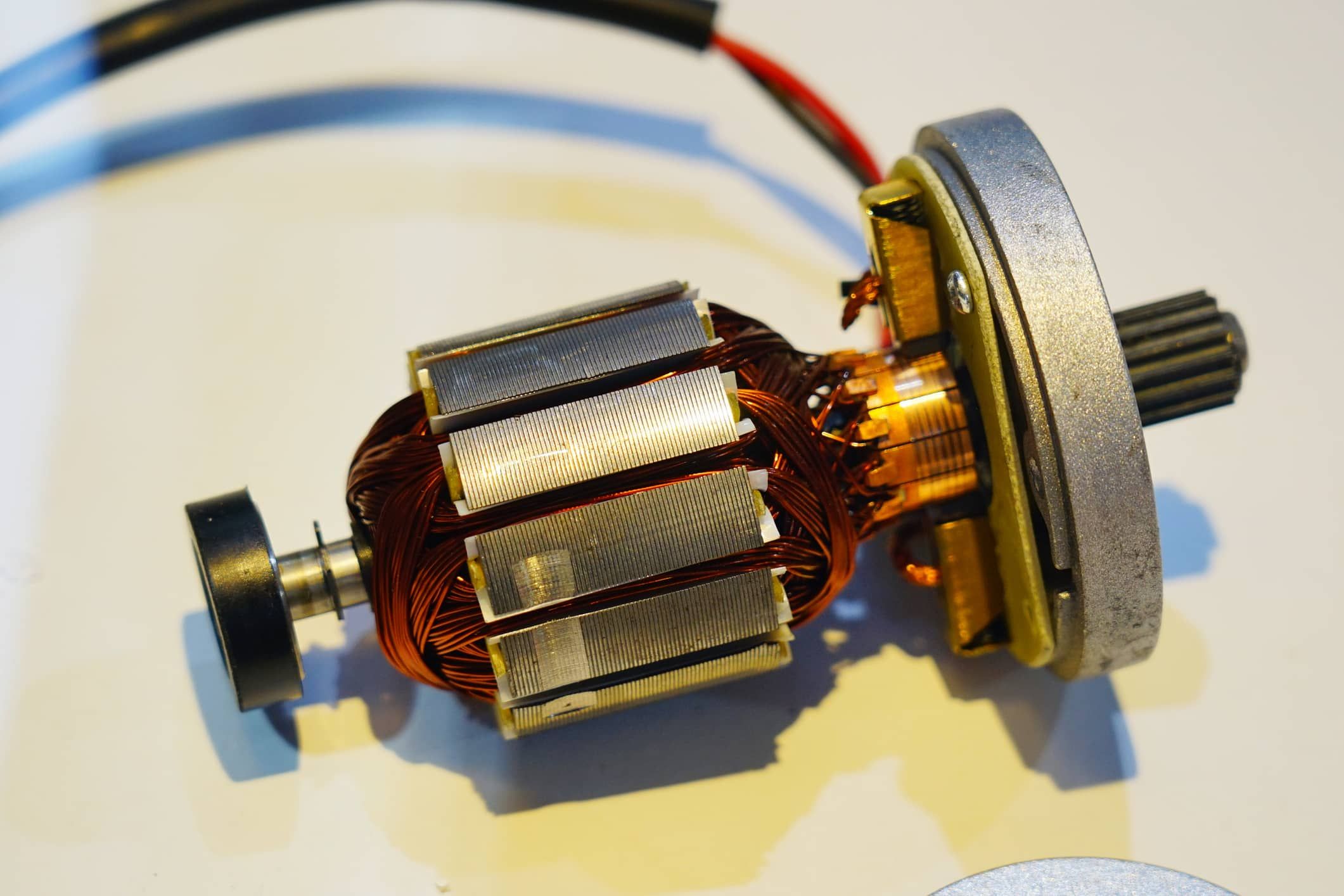

DC electric motors are electrical machines in which the electrical energy of the network is converted into mechanical energy.

These motors are used when a constant mechanical moment on the shaft is required.

DC motors can be seen all over the place:

-

Industrial drives

-

Lifting devices

-

Drilling rigs

-

Electric transport

-

Automotive

-

Defense industry

Need these products?

Other industries

- Home

- Our industries

- Electric motors and generators

we will contact you to discuss

the details

-

This email address is being protected from spambots. You need JavaScript enabled to view it.