450 Avenue Abbé Kahozi Quartier Makutano Commune de Lubumbashi Ville

Rolled Metal & Pipeline Equipment

Steel grinding balls are used in mining, coal, cement and other industries in the mechanisms of ball mills, performing the function of grinding bodies.

We offer:

-

Grinding Balls (Forged, Cast, Chromium)

-

Welded, Seamless Metal Pipes

-

Galvanized Pipes, Stainless

-

Plastic HDPE Pipes

-

Flanges, Pipeline Parts

-

Shut-Off And Control Valves

Grinding Balls (Forged, Cast, Chromium)

Grinding balls are used for grinding ferrous and non-ferrous metal ores, cement clinker, refractories, minerals, ceramics, coal, slag, construction and other materials in ball mills.

The durability of steel grinding balls is largely determined by the properties of the steel used to make them. At the same time, the operating conditions of the grinding balls impose mutually exclusive requirements on them: high hardness, wear resistance and impact strength.

Cast iron grinding balls with a high chromium content are used in cement and mining industries.

Welded, Seamless Metal Pipes

Electrowelded pipe - a sample with one seam extending along the entire length, made of sheet metal or strips by molding or welding.

Rolled metal is divided into 4 types: longitudinal, spiral, water and gas, profile.

Seamless pipe is a one-piece metal construction with no connection types.

Our industries

Galvanized Pipes, Stainless

Stainless steel is an ultra-strong material. Due to the content of chromium in the composition of the alloy "stainless steel" has excellent anti-corrosion properties and is resistant to various environmental influences. The main advantages of structures made of this metal are the following advantages:

-

Durability of operation: from 45 - 50 years.

-

Strength. Stainless steel is resistant to pressure drops and can be used at both high and low temperatures.

-

Hygiene. The material has no pores or cracks, which means it does not promote the penetration of bacteria and fungi into the interior, and also has an attractive appearance.

Galvanized metal gets its name from the specialized coating of steel sheet with a thin layer of zinc, which prevents corrosion by moisture and oxygen.

Galvanized steel has the following performance characteristics:

-

Service life - up to 25 years with a 60 micron layer of zinc coating.

-

High ability to withstand mechanical loads by rolling, forging, bending, drawing, stamping.

-

Resistant to pressure loads.

-

Resistant to temperature extremes.

-

Low electrical conductivity.

Plastic HDPE Pipes

HDPE polyethylene pipes are used for laying pressure and non-pressure pipelines transporting water, including for domestic and drinking water supply, at a temperature of the transported liquid from 0 to 40 ° C, for pressure sewer communications and gas distribution systems, as well as other liquid and gaseous substances, to which polyethylene is chemically resistant.

HDPE pipes are designed exclusively for underground laying, they are produced in coils of 100, 200 meters and in sections of 12, 13 meters. At present, almost all work on the repair of dilapidated and construction of new water pipelines, laying of new gas networks is carried out exclusively with pipes made of low-pressure polyethylene.

Plastic HDPE pipes advantages:

-

Polyethylene pipes have a long service life. A guarantee of at least 50 years.

-

No cathodic protection is required, which means they do not need further maintenance.

-

Such pipes do not corrode and are resistant to chemicals.

-

The light weight of the polyethylene pipe greatly facilitates the installation work.

-

HDPE pressure pipes are good protection against bacteria and microorganisms.

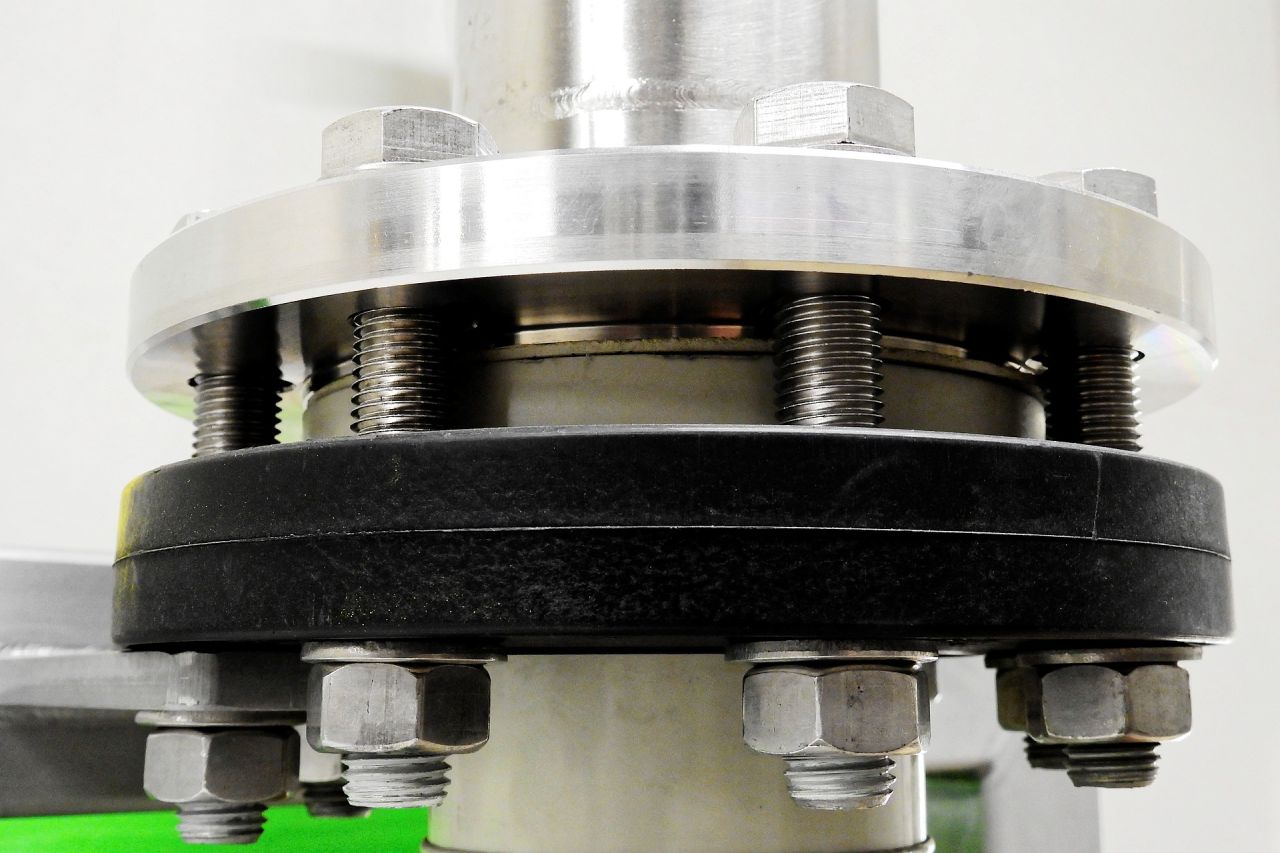

Flanges, Pipeline Parts

Flanges and elbows, gate valves and tees are part of the piping design. They make it possible to change the direction of pipe laying, to add a new branch to the construction.

Each of these parts has its own purpose.

Transitions, elbows, tees can be used to change the direction of water, technical liquids or gas. They also help change from one pipe diameter to another.

Elbows are made of steel, steel with increased corrosion and cold resistance, alloy steel.

Bends are subdivided into:

-

Steeply curved, solid bends

-

Stamp-welded steeply curved bends

-

Welded sectional bends

-

Cold rolled bends

Shut-Off And Control Valves

Shut-off pipeline fittings hermetically shut off or completely open the flow of the working medium in the pipeline. The main types of shut-off pipeline fittings are taps, gate valves, valves, dampers and butterfly valves. Shutoff pipeline valves also include drain and control pipeline valves.

Drainage valves are used to discharge the working medium from pipeline systems and various tanks, and control valves are used to supply the working medium to instrumentation and control instrumentation.

Regulating pipeline fittings regulate the parameters and flows of the working medium in the pipeline. Depending on the parameters of regulating the working medium in the pipeline, the control pipeline fittings are designed to regulate the flow of the working medium, regulate the medium pressure and liquid level, as well as mixing various media. The main types of control pipeline valves are gate valve and a shut-off and control valve, a mixing valve, a pressure regulator and a level regulator, control ball valves and control valves. Pipeline fittings are used to reduce the operating pressure in the pipeline, and shut-off and control valves are used both to shut off and to regulate the flows of the working medium in the pipeline.

Need these products?

Other industries

- Home

- Our industries

- Rolled Metal and Pipeline Equipment

we will contact you to discuss

the details

-

This email address is being protected from spambots. You need JavaScript enabled to view it.